ZF Aftermarket product portfolio

Steering and suspension parts for passenger cars and LCV from ZF Aftermarket are top-quality safety components that are subject to special diligence during design, production and assembly. After all, they have to provide the best possible safety conditions for every driving situation. A car may have as many as 70 chassis components.

The LEMFÖRDER product portfolio

OEM quality for the automotive aftermarket

Steering and suspension parts for passenger cars and LCV by LEMFÖRDER are high quality replacement components for your vehicle. Find out more and discover the LEMFÖRDER portfolio at a glance.

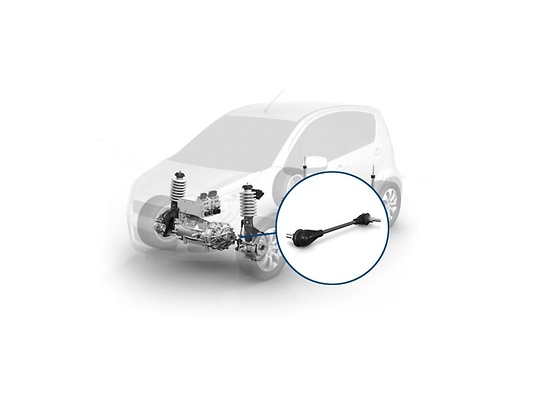

LEMFÖRDER stabilizer links

A key component to maintaining a vehicle’s stability on a curve incline or driving on uneven surfaces is the cohesive and reliable interaction of all chassis components. LEMFÖRDER stabilizer links, also known as sway bar links, transmit forces between the chassis and bodywork and ensure maximum function and driving comfort at all times.

Depending on the type of construction, stabilizer links in the front axle and/or in the rear axle of the car create the necessary connections which guarantee an optimal interaction of wheel guide and stabilizer. Sway is minimized, thus ensuring steady and safe road holding.

As an alternative to conventional steel stabilizer links, LEMFÖRDER has developed sway bar links made of weight-saving high-tech materials to production maturity. A lightweight innovation from ZF, for example, is a pendulum support in hybrid construction. It is made of carbon fiber reinforced plastic (CFRP), polyamide and high-strength steel. The intelligent mix of materials reduces weight without making the product more expensive. In the development of electric vehicles in particular, the aim is to reduce weight in order to ultimately achieve higher ranges and longer battery life.

The ball joints at both ends of LEMFÖRDER stabilizer links meet the highest demands. The high quality material selection and workmanship ensure improved joint guiding behavior, ideal sealing, minimized noise transmission and a long service life.

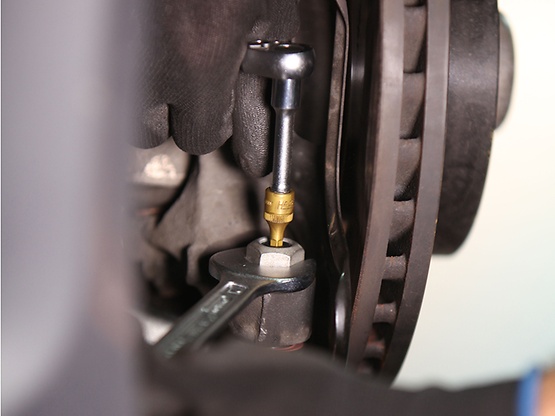

Replacing a stabilizer link

We describe all the signs and symptoms of a detective stabilizer link or coupling rod and the replacement on a Mercedes Benz C220 (S204) step by step.

LEMFÖRDER tie rods

Optimum straight-line running of a car ensures driving comfort, controllability and reduced tire wear. To ensure that passenger cars, vans and light commercial vehicles always stay on the ideal track, high-quality LEMFÖRDER tie rods should always be used for repairs. They perfectly transfer the steering movements of the driver to the front wheels of the vehicle and enable the workshop to adjust the toe-in precisely and sensitively.

LEMFÖRDER tie rods for passenger cars, vans and light commercial vehicles ensure precise steering and safe handling. The forces introduced into the steering gear are transmitted via the inner axial joint through the tie rod to the outer ball joint, the tie rod end piece. A thread in the middle of the wheel allows for sensitive adjustment of both wheels.

The connections and joints of the tie rod in particular place high demands on the design. LEMFÖRDER offers a wide range of high-quality solutions, optimized for installation spaces and the materials. Know-how acquired over decades in research and development pays off, especially with LEMFÖRDER products for the aftermarket.

The steering gear-side tie rod joint is referred to as axial joint. It can transmit axial forces of up to 25 kN. The axial joint is mainly used on rack-and-pinion steering systems.Angles of up to 60° are possible here. LEMFÖRDER produces various designs of a high quality:

- Housing with threaded pin.

- Housing with internal thread.

- Housing with tapped hole with vibration-damping rubber element.

The wheel-side angle joint transmits the radial forces from the tie rod to the steering knuckle. Complex axle configurations place high demands on the design of tie rod ends.

LEMFÖRDER offers its customers solutions optimized with regard to installation space and material. This expertise is used for the production of quality-tested spare parts.

One component of a car's steering system is the steering lever, which experts also call a relay lever or pitman arm. The steering lever for cars, vans or light commercial vehicles is an important component for the optimum transfer of the steering motion to the wheels. LEMFÖRDER steering levers are robust and reliably manufactured, durable products.

Broken outer or inner tie rod?

Check our step-by-step guide on how to replace a defective tie rod.

LEMFÖRDER control arms

In order to ensure safe vehicle handling for the driver, even in the event of extreme roadholding, it is important that the movement of the wheels is transferred quickly and precisely. For this purpose, intelligently designed control arms with joints are used within the wheel suspension.

Securely in contact with the wheels

LEMFÖRDER provides many different, vehicle-specific types of control arms, also for complex axle constructions: from guide rods, track rods and tension struts via control arms through to suspension ball joints or supporting joints. In the case of independent suspensions, the wheel carrier can be connected to the vehicle body with up to five control arms. Depending on the customer requirement, the components are either set up for comfortable or dynamic driving properties. Depending on the construction type, either 2-point links, 3-point links or, on rare occasions, 4-point links are used. Besides steel control arms, LEMFÖRDER also develops and manufactures light, premium aluminum control arms for cars and vans.

The control arms undertake the task of wheel guidance and frequently also transfer spring, damper and stabilizer forces.

Control arms offer many advantages:

- Accurate wheel guidance

- Increased driving comfort due to vibration damping

- Precise individual steering behavior which increases driving safety

- Perfect wheel guidance and control arm connection due to precisely adjusted ball joints and link mounts

Tailor-made drivability

Dynamic or comfortable? When it comes to the independent suspension, it depends, among other things, on the design of the control arms which connect the vehicle body with the wheel and its tires.

LEMFÖRDER transverse control arms are precisely tailored to the individual requirements and driving properties of a vehicle. Furthermore, alternative materials such as aluminum, which make the wheel suspension lighter overall, are used in the manufacturing process. Lightweight design is one of the key technologies when it comes to reducing the energy consumption of vehicles.

Depending on the function that a control arm assumes, either a guiding control arm or a supporting control arm is used for wheel guidance. A guiding control arm absorbs braking, driving and lateral forces. A supporting control arm supports the vehicle weight additionally. Moreover, it takes over the suspension and damping functions in the body and is designed to be more stable. Supporting control arms are often used by automotive manufacturers in the lower level of double wishbone axles and multilink rear suspensions.

Control arms are subjected to severe forces and must therefore satisfy high requirements: buckling resistance, bending strength and durability. At the same time, a low weight is desired within the context of modern, automotive lightweight construction.

A ZF lightweight solution that is already ready for production is the SMiCA control arm (Sheet Metal integrated Control Arm). The control arm requires no rivets or screw connections and is therefore up to 23 percent lighter than conventional sheet metal control arms. Furthermore, it requires less installation space and allows more design freedom when designing the chassis.

Ball joints are used in control arms, tie rods and stabilizer links, for instance. A ball joint consists of a supporting joint and ball stud and is free-moving in three directions. Traction forces, compressive forces and radial forces are transferred in these three directions with hardly any losses at all. Low losses occur as a result of friction. Therefore, LEMFÖRDER uses premium materials for the ball and shell and consequently achieves:

- Low deformability

- Excellent glide characteristics

- Outstanding damping

The exact designation of the ball joints is derived from the transferred direction of force: Angle joints transfer radial forces, axial joints transfer axial forces.

How to replace a control arm?

A step-by-step illustrated assembly guide

LEMFÖRDER suspension joints

Suspension joints by LEMFÖRDER ensure greater agility, enhanced stability and more strength, making the car safer and more durable through optimal elasticity and lower friction torques. They are integrated into the control arms, pressed-in or flange-mounted. Alternatively, they can be pressed or screwed into the wheel carrier.

Lighter, smaller and stronger

With our unique ball joint tempering process, service life is greatly extended, ensuring greater agility, enhanced stability and more strength, making the car safer and more durable through optimal elasticity and lower friction torques.

- High grade material ball pin – with tensile strength of up to 1100N/mm2 following ISO standards of 6892-1.

- Heat treated forged housing – with hardness of up to HV 380 to provide better durability and promote safety.

- Precise application of special greasing – applied evenly to the whole ball for longer life and better steering.

- Lightweight and corrosion and chemical resistant – the polymer bearings offer a much smoother steering returnability.

There’s a reason that every third ball joint produced worldwide is made by LEMFÖRDER.

Suspension ball joint

The (wheel) suspension ball joint establishes the connection and, consequently, the support between the front axle control arms and the axle body/carrier (steering knuckle). Its task is to guide the wheel carrier and wheel, to enable the spring deflection of the wheel and to permit the steering movement on the front axle. It is always installed at the triangle apex of the control arm. The height fixation is performed via the ball stud. The ball joint should be easy to move, low in flexibility, maintenance-free and noise-insulating. These four, partly contradicting, requirements are met at LEMFÖRDER, for instance thanks to premium plastic shells in the joint.

Supporting joint

In terms of design, the suspension ball joints and the supporting joints are only marginally different from one another. The supporting joint is located on the opposite side of the suspension ball joint, assembled in the steering knuckle. It absorbs forces in all directions and can be installed in a suspended or vertical manner. The ball joint housing is usually attached in the control arm and the ball stud is usually attached on the inside of the steering knuckle via its conical taper or a cylindrical dog point. Advantage: This mounting is maintenance-free.

Cross-axis joints

Cross-axis joints are primarily installed on the rear axle. They consist of a ball with cylindrical taper on both sides and a continuous bore in the middle. Although they are similar to the ball joint in terms of function and structure, their anchorage corresponds to that of rubber bearings. In contrast to rubber bearings, cross-axis joints are able to transfer extremely high dynamic forces and have no aligning torque. Cross-axis joints are preferably used if a stiff control arm connection is desired – in sports cars or light commercial vehicles for instance.

LEMFÖRDER rubber-to-metal components

How does the vehicle respond in the event of road unevenness, braking under maximum load and evasive maneuvers?

The elastic connection of premium rubber-to-metal components between the individual chassis components has a decisive impact on this. LEMFÖRDER rubber bearings for the chassis ensure sound absorption, ideal steering behavior and driving stability, even in critical situations.

The product range consists of suspension strut mounts and all different kinds of axle bearings. In the case of the axle bearings, a distinction is made between link mounts, axle beam mounts, subframe bearings and stabilizer mounts. In addition to the ball joint, the rubber-bonded metal mount is the most important type of joint in the wheel guidance of the chassis. It forms the elastic connection between the individual chassis components, such as the control arm and the vehicle body or the axle carrier. Through the specific sizing and shaping of these parts, it is possible to influence the tuning of the chassis.

Rubber-to-metal components have a decisive influence on driving characteristics and driving safety. The vulcanized connection between the metal and rubber transfers compression and shear forces and simultaneously insulates oscillations, vibrations and structure-borne noise. They are used where flexible but also damping connections are required at the same time: Up to 15 different rubber-to-metal components are installed in a passenger car.

The LEMFÖRDER composite parts are therefore designed in an innovative manner and are geared to a particularly long service life.

Conventional mounts are intelligently designed rubber-metal or rubber-plastic constructions that provide mechanical damping.

Hydraulic mounts or hydromounts additionally work with a damping through oil. Within the rubber element, the liquid ensures a flow resistance that softens jolts and vibrations. Hydraulic bearings are used wherever an elastic mounting with frequency-dependent damping is desired.

Hydraulic bearings may be:

- Link mounts

- Axle beam mounts and subframe bearings

- In the driveline: engine mounts

Checking rubber-to-metal components

How does the mechanic check rubber-to-metal components, how are damages and displacements detected and how are components assambled?

Replacing strut mounts

Check the strut mounts and identify any defective strut bearings. Find instructions on changing strut mounts in our useful tips.

LEMFÖRDER Service Pack

A careful and competent repair is even easier now with the LEMFÖRDER Service Pack: It contains all the fastening parts required for assembly - of course in the same OEM quality as the LEMFÖRDER spare part. This enables the workshop to carry out repairs quickly and safely.

We, as an OEM supplier, recommend that workshops replace all fasteners such as bolts, nuts, etc. for safety reasons when installing spare parts in the vehicle. If adjacent components also need to be removed to fit the new part, the fasteners should be replaced here as well.

The LEMFÖRDER Service Packs for passenger cars include all the fitments for installing a LEMFÖRDER product and can also be ordered as an option. The parts in the fastening set are of course manufactured to the same precision and OEM quality as our high-quality OEM spare parts.

The LEMFÖRDER original assembly accessories offer the following advantages:

- Complete fastening set with all fasteners – where applicable also including fasteners for adjacent components

- OEM quality down to the smallest screw

- Repair based on the manufacturers' original instructions

If the main component and the corresponding mounting kit are ordered together, this is considerably faster and more efficient, as the other components do not have to be identified and ordered separately.

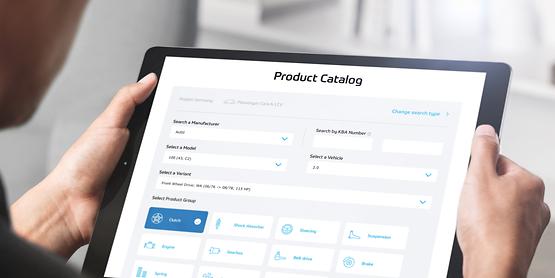

When ordering from the online product catalog, check if additional fastening sets are available or required for the spare part you order (selected products already come with the respective accessories).

LEMFÖRDER Service Packs are available for:

- Suspension joints

- Control arms

- Link mounts

- Stabilizer link

LEMFÖRDER Active Kinematics Control

For decades, auto developers have sought to adjust rear axle tracking, thus improving almost every driving situation. Now, ZF engineers have achieved it, thanks to AKC® (Active Kinematics Control) and the modular axle concept mSTARS.

AKC® is a state-of-the-art suspension system capable of adjusting its characteristics as the vehicle is driving along, AKC® means more dynamic and agile cornering, improved driving stability and safety at high speeds, as well as all-round easier parking and turning. Another example of true innovation, technological achievement and automotive excellence.

mSTARS is a modular system that enables a basic axle to be converted to an electric or a standard powertrain module and/or an AKC® rear axle steering system, depending on the customer’s request. Only minor modifications to the car body are required to install the system, and it can be fitted in all kinds of passenger cars, from compact mid-size vehicles to luxury and sports cars.

Advantages:

- Versatile modular design

- Compatible with complex standard multilink rear suspensions

- Offers enhanced comfort, agility and stability

The TRW Product Range

Shaped by innovation and history

With coverage that encompasses 90% of the European vehicle parc, we can supply your business with precisely the aftermarket parts that you need to satisfy your customers, every time.

The highly professional TRW innovation team is completely focused on creating the most advanced products on the market, always engineered and tested to the highest possible standards. This means that we are able to deliver the most efficient, safe and durable Steering and Suspension products to you and to your customers.

TRW remanufactured steering racks and pumps

Choosing TRW Aftermarket is an exceptional way of guaranteeing the outstanding quality and service that will keep your customers coming back for more. Our selection of steering and suspension products have gained industry recognition for their durability, strength and performance, making us the number one choice when it comes to steering systems.

- Market leader on remanufactured column drives

- Power steering pump coverage of more than 87% across Europe

- Huge and in-depth knowledge of rack and pinion parts – supplying steering racks and pumps for a quarter of the vehicles in the world

With TRW steering racks, pumps and column drives fitted in one-in-three European vehicles, and a quarter of vehicles throughout the world, we have a distinct advantage over other aftermarket suppliers, with an innate understanding of a large proportion of the rack and pinion steering system market place. Through our innovative service we can remanufacture steering racks, pumps and column drives and offer them to you from stock, helping to reduce costs as well as the impact on the environment.

It’s our own in-house testing processes that make our remanufactured steering systems perform so well. These processes cover: acoustic measurements for driver comfort, strength tests, environmental resistance, wear tests, assembly technique and road testing. All of these examinations mean that the steering system is equipped and prepared to deal with the real world, offering tangible safety and protection benefits for drivers.

Steering system remanufacturing is the only way to ensure that older vehicles continue to perform safely on the road. Our high standards and rigorous testing processes offer peace of mind to you and your customers, and this is reinforced by the TRW guarantee.

We design and produce the original steering and braking systems for several major manufacturers, so we understand the importance of upholding the highest safety standards. All of our steering products are tested to original equipment standards, which helps us to meet and exceed the international regulations.

With more than 4,000 engineers, scientists, designers and technicians working across 27 countries TRW can deliver a comprehensive service to more than 40 vehicle manufacturers. This gives us a unique standing, helping us to outperform our competitors in the steering and suspension market place.

From our factory in the Czech Republic, TRW runs an all-makes programme for remanufacturing steering gears and pumps across Europe. As you can see below, we cover a huge proportion of the European aftermarket with a wide range of products.

Steering gear line:

- 536 types of assisted steering gear parts

- 175 types of non-assisted steering gear parts

Power steering pump line:

- 357 types of hydraulic steering pump parts

- 48 types of electrical steering pump parts

Column drive line:

- 232 types of electrical column drive parts

TRW steering linkages

The steering linkage is a crucial part of the steering system, connecting the front wheels and enabling them to move in a functional way. Given the importance of the steering linkage, it is critical that all cars are fitted with high quality parts, which TRW can provide to help you offer great service for your customer.

- Improved performance of tyres which lowers the chances of vehicle-roll

- More than 4,800 parts to choose from

- Corrosion resistant stabiliser links made from glass-fibre reinforced plastic

- Reduced weight and damping vibrations

- Two-seat design for tie-rod ends which means no spring and therefore longer life

Our standing as an industry leader in steering systems is highlighted by our huge product range, covering more than 4,800 parts and 92% of the European vehicle parc. This means you can trust TRW to deliver exceptionally high standards of performance and safety. The benefits of choosing a TRW steering linkage includes:

- Guaranteed safety improvement

- Continuous advancement through outstanding research and development

- Original equipment (OE) quality

- Extreme testing process

- Expert training and guidance

If the steering linkage in a vehicle isn’t working properly then the occupants could be in danger. The chances of vehicle-roll during cornering are increased by a failing stabiliser link due to possible over steer, while a broken stabiliser link can also knock out or tilt away. As well as generating an annoying noise while the vehicle is running, a damaged steering linkage could affect the performance of the tyres or braking, which also has the potential to be dangerous for the driver.

With a wide and varied product range, we cover a huge selection of requirements, which is why we’re your one-stop solution in the aftermarket. Manufacturing all sorts of linkage products from Tie rod ends to control arms and ball joints, we have developed forged aluminium, forged steel, nodular cast iron and stamped steel to give you lightweight parts for efficient and flexible performance.

With corrosion resistant stabiliser links made from glass-fibre reinforced plastic, you can give drivers safe, efficient and strong performances at all times. The use of such high-quality materials allows us to reduce the weight and damping vibrations of our stabiliser links. And where glass fibre material is unsuitable due to space restrictions, we’ll supply proven steel steering linkages.

Our tie rod ends use a two-seat design as standard, which means there is no need for a spring, which will extend the life of the part. A 24-hour salt spray test means that they can be trusted at all times, but to be sure we’ll also perform dynamic and elasticity tests as well. TRW tie rod assemblies are all adjustable to the needs of each individual chassis, and with a large selection, we’ll even provide a full OE standard repair kit to go with them.

Other products in the portfolio include:

- Front and rear toe links – offering better straight-line stability

- Centre links – ensuring an efficient, straightforward connection with the idler arm

- Idler arm – providing pivoting support for the steering linkage

- Pitman arm – converting the angular motion of the sector shaft to linear motion

- Bellows – allows expansion and compression of a joint

The key to producing such market leading products is all in the intense testing process that we carry out on all of our steering linkage parts. Visual checks help us to assess quality variances where we examine physical performance for the following:

- Break away torque

- Rotational torque

- Radial elasticity

- Pull out force

- Endurance test

TRW Track control arms

Choosing TRW Aftermarket is a simple and straightforward choice, with our control arm parts providing the following tangible benefits for drivers.

- Improved fuel economy with optimised weight and shape through finite element techniques

- Temperature resistant parts that perform in all conditions

- More than 1,000 types of control arm components to choose from to cover all vehicle types

- Enhanced ride handling and performance with a collection of rubber, metal and hydraulic bushes

With the most rigorous testing process employed across all of our parts you can be sure that TRW products are the best in the business.

TRW Track Control Arms come in a range of shapes and sizes depending on the vehicle application. Finite element techniques from our expert technicians also help to optimise the weight and shape of the control arms.

The current TRW Control Arm range offers you more than 1,000 types of control arm component. This vast array of parts allows us to provide specialist help and support to a wide range of vehicle types. With upper and lower control arms for front and rear suspensions, we really do have everything covered when it comes to control arms.

A track control arm is the hinged suspension link that connects the chassis and the suspension that carries the wheel. Attached with a single pivot, normally a rubber bushing, the control arm can adjust the position of the outboard end while sustaining the radial distance from the inboard mount. A track control arm is one of the most mechanically impressive parts of the suspension system, which means it is important to replace them when they become worn or broken.

Often the reason a replacement is required is due to the ball joint or bushing being worn out, but it can be very difficult and expensive to replace these components separately. This is why TRW believes that replacing the whole part will be more efficient and provide a longer lasting fix. Drivers should also consider changing the control arm when the wheel has been damaged due to an accident.

Our selection of Upper and lower Track Control Arms features:

- Aluminium forged Track Control Arms

- Aluminium cast Track Control Arms – which are extremely low weight to ensure high performance levels

- Steel forged Track Control Arms

- Steel stamped Track Control Arms

Ball Joints also feature in our steering and suspension range of parts, which are crafted using state-of-the-art techniques to make sure that they deliver an exceptionally high performance. These parts are all temperature resistant so that they can perform in any conditions as well as offering low-torque and high comfort solutions. With a range from 25mm to 42mm, and with integral as well as non-integral designs, TRW caters for every vehicle type. TRW also produces a mixture of rubber, rubber and metal and hydraulic bushes as part of the range.

TRW stabiliser links

A stabiliser link performs a crucial role in the performance of any vehicle, connecting other parts of the suspension set up that absorb the shocks from potholes or bumps in the road. Therefore stabiliser links or stabiliser bars need to be performing at their best to guarantee driver safety and comfort.

- Parts made from corrosion-resistant steel, aluminium and glass fibre reinforced plastic – reducing the weight

- A more comfortable ride with the impact of damping vibrations lowered

- Proven steel stabiliser links when glass fibre models cannot be fitted

- Certified manufacturing sites meaning economical and efficient production

- More than 80% of TRW parts made in TRW factories – allowing us to uphold quality standards

Every stabiliser link we produce is tested to the extreme, which means you can have peace of mind that it will perform when it is needed most. With Original Equipment (OE) designs, you can trust TRW to deliver the very latest and best safety equipment.

The replacement of a faulty stabiliser link with a new TRW stabiliser link on a car has an immediate, easy to identify effect on the quality of driving. The benefits of a TRW stabiliser link are:

- Improved fuel economy

- Lower emissions

- Enhanced driving comfort and support

With years of experience in the aftermarket, TRW can supply high-quality, efficiently produced parts that make a real difference to driver safety on the road. As designers and manufacturers of OE components, you can trust TRW to provide exceptional products that can meet a wide range of vehicle types, designs and needs.

TRW stabiliser links come in either corrosion-resistant steel, aluminium or glass fibre reinforced plastic. Every stabiliser link is constructed using the very latest techniques with advanced equipment from our workshops around the world, allowing us to utilise the skills of more than 4,000 scientists, designers, engineers and technicians. With more than 80% of TRW parts sold into the aftermarket made in TRW factories, this commitment to quality is always upheld.

TRW’s corrosion-resistant stabiliser bars are made with glass fibre reinforced plastic, which means that weight is reduced and the impact from vibrations is improved. When glass fibre models cannot be fitted due to loading conditions or space restrictions, TRW can still supply a proven steel stabiliser bar instead.

![ZF Service [pro]Tech ZF Service [pro]Tech](/media/master/service-images/zf_workshop_protech_group-in-front-of-workshop_bs_32_xl_4.jpg?v=3456034853)

![[pro]Academy [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)