ZF Aftermarket product portfolio

ZF Aftermarket supplies a full range of parts for a vibration-free drive, including shock absorbers, suspension struts and suspension-strut inserts for virtually any model of motor or light commercial vehicle. Our high-quality shock absorbers for passenger cars keep workshops and customers on terra firma.

SACHS

Enhanced safety and driving comfort

SACHS car shock absorbers are of the highest quality, which is one reason why numerous well-known automotive manufacturers fit them as standard in new vehicles. Every year, over 10 million new cars roll off the assembly line fitted with SACHS auto shocks. Equally, SACHS applies its OE expertise to spare parts production, so its aftermarket shock absorbers are always state-of-the-art, which means a safer, more comfortable and contemporary drive. No matter what challenges the road presents, the chassis performance and dynamics SACHS aftermarket shocks provide ensure perfect road grip and cornering.

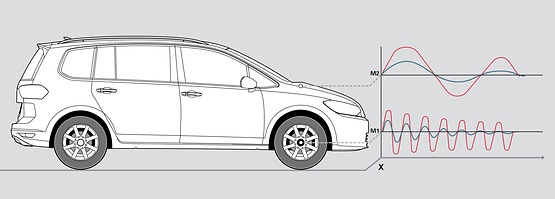

A passenger car shock absorber, together with the coil spring, forms the end link between the suspension and the vehicle body. It is a vital safety-related component that reduces vibrations in the suspension spring, slowing it down and thus reducing vehicle body movement. The term “shock absorber” is therefore actually misleading - strictly speaking, it’s a “vibration absorber”.

The impact of driving over uneven ground (X) is absorbed by the suspension. It prevents the sprung masses (M2 = vehicle body and payload) from coming into contact with the unsprung masses (M1 = axle and wheels). Following compression, the suspension springs attempt to push the sprung masses away from the unsprung masses. The shock absorbers allow the resulting axle and body vibrations to subside. (Red: without vibration absorber, blue: with vibration absorber)

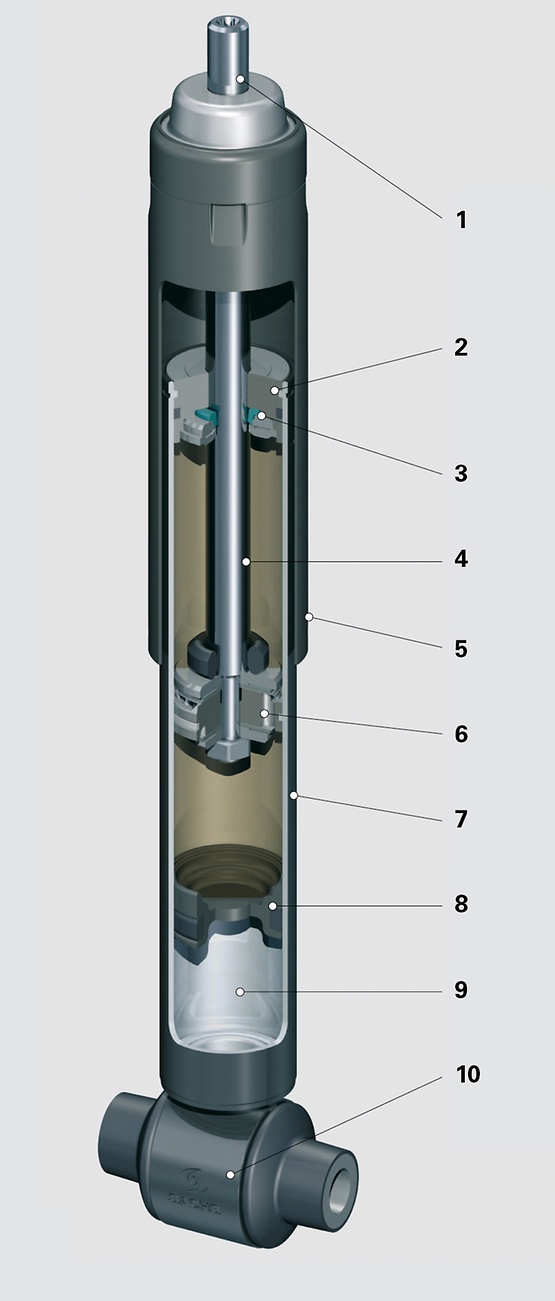

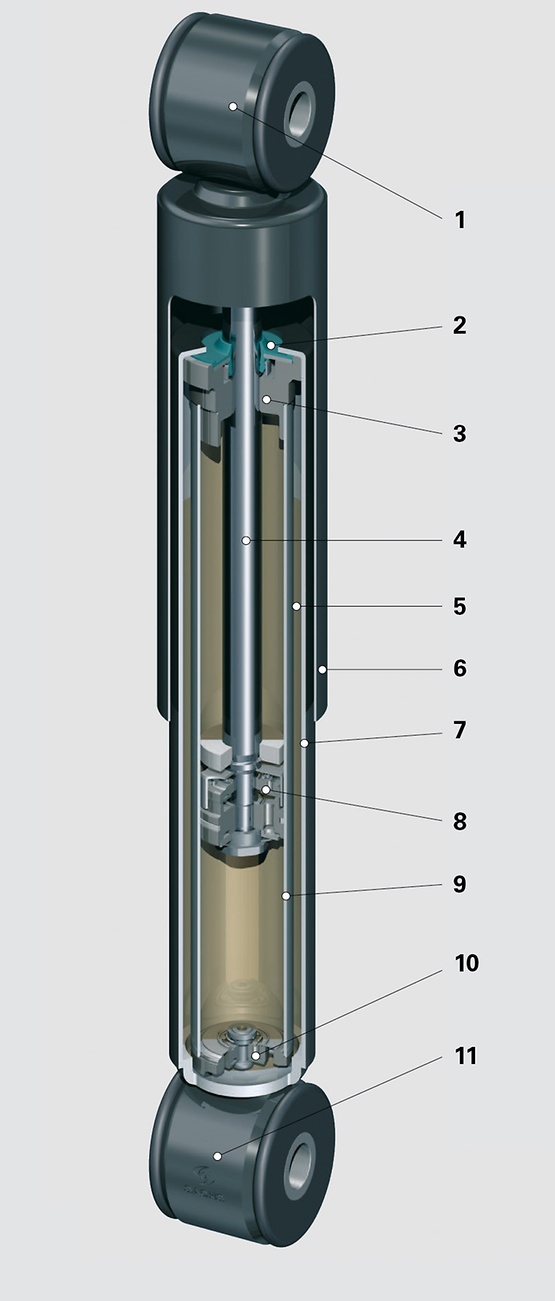

In gas-filled monotube dampers, the working cylinder is filled with oil and gas at a high pressure of around 25 to 30 bar. The floating separating piston provides absolutely leak-proof separation between the oil and the gas.

The SACHS monotube damper can be installed in any position. It operates at higher pressure than the twin-tube damper. The advantages of this are that it makes the lamellar valves in the piston highly responsive and also prevents foaming or bubble formation in the hydraulic oil.

1. Mounting joint

2. Piston rod guide

3. Piston rod seal

4. Piston rod

5. Protective tube

6. Piston valve

7. Working cylinder

8. Separating piston

9. Gas cavity

10. Mounting joint

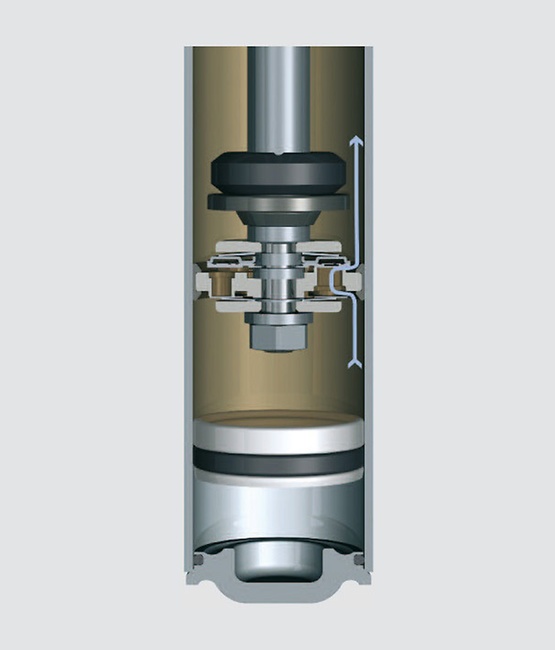

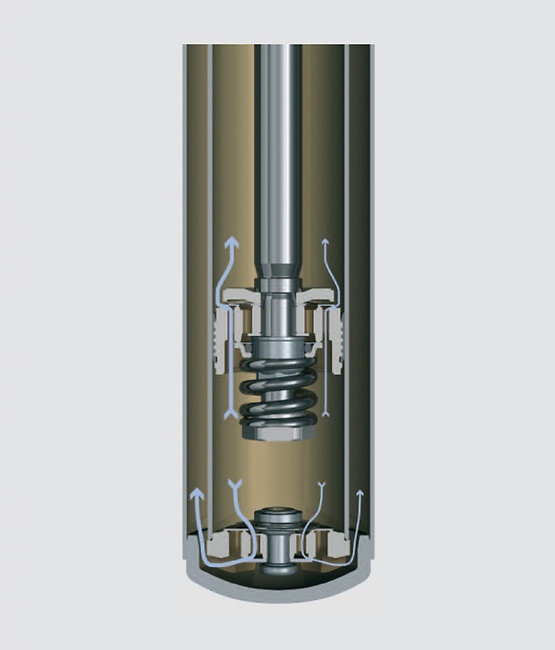

Compression stage

Vehicle vibrations push the shock absorber together.

The piston valve provides resistance against the oil that flows up from the cavity below the piston. This slows down the downstroke.

The gas cushion compresses by the volume of the retracting piston rod.

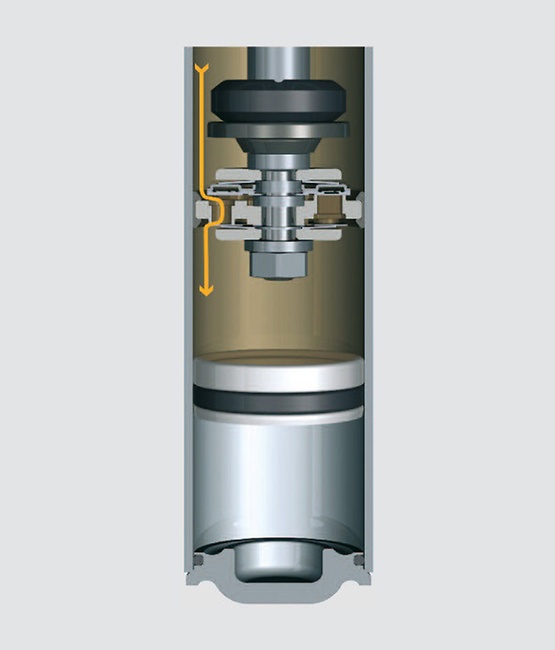

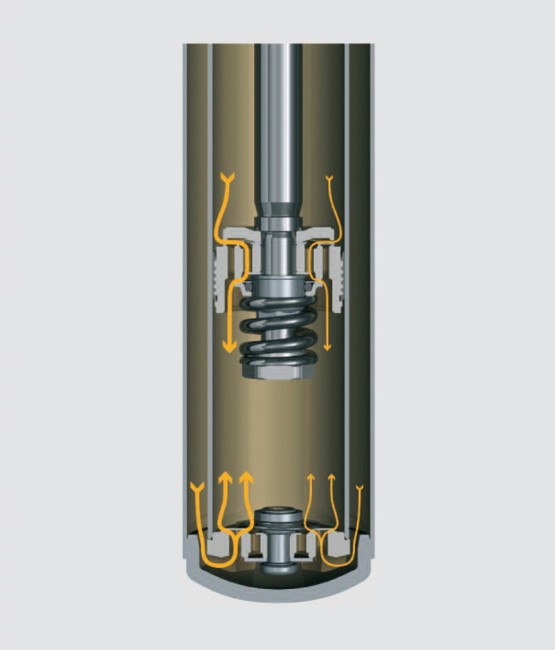

Rebound stage

Vehicle vibrations pull the shock absorber apart.

The piston valve provides resistance against the oil that flows down from the cavity above the piston. This slows down the upstroke.

The gas cushion expands by the volume of the extending piston rod.

Twin-tube dampers have two oil-filled cavities: the working cavity in which the piston and piston rod move, and the compensating cavity. The compensating cavity is located between the working cylinder and the reservoir tube, and is filled 2/3 with oil and 1/3 with air or gas. As a result, the twin-tube damper has a shorter installation length than its monotube equivalent.

The damping force characteristics of the twin-tube damper are specifically designed for each vehicle type in that they are adapted to the vehicle weight, axle design and suspension springs.

1. Mounting joint

2. Piston rod seal

3. Piston rod guide

4. Piston rod

5. Compensating cavity

6. Protective tube

7. Reservoir tube

8. Piston valve

9. Working cylinder

10. Bottom valve

11. Mounting joint

Compression stage

Vehicle vibrations push the shock absorber together, with the bottom valve determining the damping.

The oil displaced by the retracting piston rod flows into the compensating cavity, where the bottom valve resists this flow and thus slows down the stroke.

The piston valve is open. In this state it functions as a non-return valve.

Rebound stage

Vehicle vibrations pull the shock absorber apart, with the bottom valve determining the damping.

The piston valve provides resistance against the oil that flows down from the cavity above the piston. This slows the upstroke.

Via the open non-return valve in the bottom valve, the oil required back in the working cavity can flow out of the compensating cavity without obstruction.

CDC - electronic damper control

SACHS CDC dampers (Continuous Damping Control) for passenger cars stand for perfect damping in any situation. State-of-the-art technology continually records all the variables that are relevant to damping and adjusts the damping force to the external conditions using a valve. The damping force is varied depending on the road condition, payload weight or vehicle handling.

With more than 14 million units installed, SACHS CDC dampers for cars are among the brand's most popular products. The electronic damper control CDC has a wide range of advantages. An overview of the key advantages is provided here:

- Stability even in critical driving situations

- Reduced stopping distance

- More ride comfort, safety and dynamics

- Individually adjustable chassis characteristics

- Damping force for each wheel adjusted within split seconds

SACHS CDC dampers for cars allow for efficient damping optimization for each wheel within split seconds. This enables maximum stability even in critical situations. The driver benefits from short stopping distances, faster steering responsiveness and more control when changing lanes. SACHS CDC dampers for PC are the prime choice when it comes to maximum safety, dynamics and ride comfort.

SACHS CDC dampers for PC feature an electronically controlled proportional damping valve. Sensors monitor all influences, from the road condition and payload to the driver's actions. A control unit then exactly regulates the damping force.

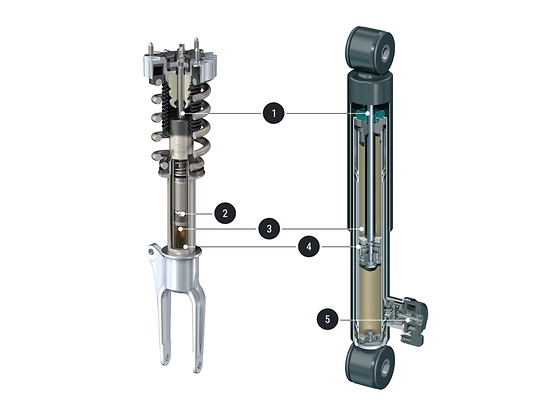

Internal and External CDC valve

The internal CDC valve (2) is mounted inside on the base of the piston rod (1). The valve is connected to the control unit by a cable led through the piston rod.

The external CDC valve (5) is mounted outside on the damper tube and connected to the control unit via a watertight plug.

Further components:

- Working cylinder (3)

- Oil compensation chamber (4)

The skyhook principle of CDC technology

The motions of the vehicle body are modulated so that the driven vehicle seems suspended from a hook fastened to the sky. The vehicle level is always kept as close as possible to the center position ‒ regardless of the currently prevailing driving and road conditions.

Optimized steering and smooth suspension: Air springs for passenger cars

When it comes to shock absorbers, SACHS’ quality, reliability and performance is unequalled. Now we take our damping product range even further, with new SACHS Air Springs.

Discover our newest addition to the SACHS product range in our video for Air Springs for passenger cars.

Modular suspension struts and shock absorbers – as the name already implies – are modular in design. They are fabricated without weld joints and have high-quality zinc plating. This means they are very well protected against corrosion and have extremely long service lives.

With these modular suspension struts and shock absorbers, ZF Aftermarket has introduced a completely new kind of shock absorber for cars in the subcompact segment. Thanks to innovative production processes and corrosion protection, these products are top quality, reliable and long-lasting.

Like the technology, the development goal is just as new in that ZF initially designed the modular shock absorbers and suspension struts as innovative technology products specifically for the aftermarket; in volume production, they will be available only at a later date. In fact, these new products are a good example of the elevated status that the aftermarket enjoys and how customers in the spare parts market can benefit from the expertise of the entire ZF Group.

Innovative manufacturing process

At first glance – and apart from the missing paint – modular products look like conventional spare parts. However, if you look more closely, there are significant differences. The innovative suspension struts and shock absorbers are modular in design and fabricated without weld joints. ZF is thus introducing new and ground-breaking joining technologies in shock absorber design.

Advanced corrosion protection

Instead of anti-corrosion paint, the modular suspension strut and shock absorber are galvanized with a high-quality finish. In addition to effective corrosion protection, this finish gives the suspension struts and shock absorbers an unusual look that accentuates the very high quality of the products and instantly associates them with the manufacturer ZF.

Modular shock absorbers and suspension struts help preserve the environment

Our engineering team has developed new processes in suspension strut and shock absorber production that have noticeably reduced energy consumption; these products also help reduce CO2 emissions. The environment therefore also benefits from the ZF innovation. However, this intelligent production technology has another strategic advantage in that it allows a much faster response to market needs with production capacity at new locations.

From suspension spring to service kit: complementary products for passenger cars

A shock or damper is only as good as its adjacent components. We therefore advise that the complementary products in passenger cars, such as the top mounts, service kits and suspension springs, be checked every time the shock absorbers are replaced.

Suspension springs for passenger cars

Suspension springs are the connecting element between the wheels and the vehicle body. They support the weight of the vehicle and, together with the shock absorbers, ensure optimal road hold in all driving situations and under varying load conditions. Suspension springs also compensate for bumpy roads and ensure good wheel-to-road contact. That makes them particularly important and safety-relevant spare parts for vehicles.

If the suspension springs are defective, SACHS offers a high-quality and extensive range of 3,100 products for the European and Asian vehicle market, including suspension springs and other complementary products for any and all needs.

Passenger car service kits

Service kits are part of the passenger-car complementary product range. They consist of compression stops or auxiliary springs and bellows or protective tubes and have the following functions:

- Reducing vibrations along with the shock absorbers and suspension springs

- Protecting shock absorbers and suspension springs against overload

- Protecting the shock absorbers' piston rod from salt residue, water, dust and dirt

Like all passenger-car complementary products from the SACHS brand, the service kits are of high quality. They contribute considerably to the durability of the shock absorbers.

Suspension-strut mounts for passenger cars

Another complementary product is the suspension-strut mount. It forms the top mounting point of the shock absorber. At the same time, it supports the vehicle weight, enables steering depending on the axle design, and dampens rolling noises and vibrations. The suspension-strut mount is exposed to heavy stresses in day-to-day driving as well as varying weather conditions. The consequences of a defect range from increased noise generation and longer stopping distances to the loss of precision wheel guidance. Therefore, we recommend replacing the suspension-strut mount when replacing the shock absorber.

TRW

TRW shock absorbers

You can identify the right shocks faster with us because our refined range has one of the most sophisticated application list on the market. And you can fit fast because we analyse the OE-products down to all technical details before designing our product, to make sure our shock absorbers are equivalent to original equipment.

Choosing a TRW shock absorber means:

- Innovative designs with a huge range and outstanding quality thanks to our extreme testing processes

- Fitting TRW parts is a brilliant way of offering improved safety on the road for all drivers

- Polish process for the rod results in 20% smoother surface for a better seal and longer shock absorber life

- Packaged in pairs for a complete replacement resulting in considerably higher safety of the vehicle

Covering 98% of the European vehicle parc with 1.100 part numbers, you can trust that we know what we’re doing when it comes to shock absorbers.

All TRW shocks are produced using the very highest OE quality standards to ensure that they deliver a premium performance level that helps to enhance safety, performance, comfort and protection.

The TRW range of Performance Gas and Hydraulic Plus shock absorbers includes the following:

- Macpherson struts

- Strut inserts

- Conventional shocks

- Front shock absorbers

- Rear shock absorbers

- Heavy duty shock absorbers

- Load compensating

- Steering dampers

Braking distances can be cut by up to 5% when shocks are replaced in pairs. So, because safety is our number one priority, we’re leading the market by making them available to buy in twin-packs. Changing in pairs is safer because it equalizes the damping force across both shocks. It can reduce braking distance by up to 5% on emergency stops. Furthermore, during difficult driving situations, e.g. like simulated in double lance change; an equal damping force increases the threshold before the vehicle may lose control.

At TRW we never rest on our past success, which is what helps us to stay at the forefront of the aftermarket industry. The latest shock absorber innovation from our technicians includes:

- An over-moulded Teflon piston ring, creating perfect cohesion between piston and inner tube. This also acts to reduce wear, helping drivers to have more comfortable journeys for longer.

- Polish process technology for the shock absorber rod. A level of roughness below 0.08 microns results in a perfect seal, helping to lengthen the life span of the shock absorber.

- Advanced valve discs technology. Calibrated to 1/100mm, drivers will get quicker response times from their shocks, which results in improved safety performance.

- Elastic metal discs – helping to increase the damping precision.

With a seal that is constantly lubricated, the friction level on a shock absorber is reduced dramatically. TRW shocks also have the rod hardened before polishing, which results in a 20% smoother surface for increased longevity compared to standard market specification. Oversized compression valves and strong valve retainers means our parts can deal with extreme conditions as well.

BOGE

BOGE shock absorbers

Using high-quality materials, sophisticated machining processes and special technologies, we make shock absorbers that meet every challenge and always perform at the highest level. With BOGE, you can improve the performance of your business by providing aftermarket shocks that give a winning service every time. With our shock absorbers, you have precise grip, handling and dynamics for a perfectly balanced ride that is in a league of its own.

Built to excel in all conditions

An average shock absorber has fixed predetermined damping settings, not ideal for either comfort or safety as damping forces are unable to change as driving conditions change.

In contrast, BOGE shock absorbers enhance vehicles with variable damping systems by automatically adjusting to the actual driving situation.

Precision & control

- Wheels don't jump on normal driving surfaces.

- No skidding when braking.

- No swerve tendency due to insufficient tracking in curves.

- No extended post-oscillation in the vehicle body.

- No vibrational build-up in the vehicle after successive bumps on the road.

- No rearing of the vehicle body during acceleration or plunging during braking.

Influencing performance and comfort

The shock absorber mounting (suspension strut support bearing) is the upper attachment/pivotal point between the shock absorber and chassis. This has to face many challenges, such as adverse weather conditions, which is why it is classed as a ‘wear and tear’ part.

A BOGE shock absorber mounting provides the strength and performance to support vehicle weight, enables reliable steering of the spring strut and prevents the penetration of vibrations and noises into the chassis. Most important of all, it enables better tire-to-road contact and reduced braking distance for maximum safety.

By calibrating the characteristic curve the driving performance and comfort can be strongly influenced. So, by adding our mountings when you fit a BOGE shock absorber, you can improve steering, comfort and safety – and give the class of service that wins more business and secures high customer satisfaction.

The power to deliver

- Precise wheel control.

- Optimal tire-to-road contact.

- Precise steering behavior.

- Reduced braking distance.

- Reduced noise.

- Reduced vibration.

Long lasting performance

To deliver an exceptional performance for your customer’s vehicle you need to be well prepared. Our service kits give you an advanced level of accessories that enable you to prepare the shock absorber for the challenges it will face every day on the road.

Each service kit consists of impact stop and bellows and/or tubular cable protection. These wrap the piston rod for the long-term protection of the shock absorber, giving your customer exceptional shock absorber performance and service life.

BOGE service kits enable you to excel. The protection we offer for our shock absorbers enables you to deliver the best performance for your customer’s vehicle.

Long-term protection

- Snapping caused by road unevenness, such as potholes.

- Damage to the piston rod, e.g. by salt, stones, water.

- Early shock absorber wear.

![ZF Service [pro]Tech ZF Service [pro]Tech](/media/master/service-images/zf_workshop_protech_group-in-front-of-workshop_bs_32_xl_4.jpg?v=3456034853)

![[pro]Academy [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)