ZF Aftermarket product portfolio

Rubber bearings for the driveline securely fixate the engine and transmission and increase the ride comfort for the passengers. The metal-to-rubber components in the driveline include engine mounts, transmission mounts, and torque support arms.

They form the damping connection of the engine and transmission with the chassis and secure the units in all driving situations. Furthermore, the bearings ensure that the driver and the passengers are protected against bothersome vibrations and noises. Nowadays, the LEMFÖRDER rubber-bonded metal mounts are also used for harmonizing the engine timbre.

The LEMFÖRDER product portfolio

Rubber-to-metal components in the driveline: More comfort in the passenger cabin

A solid combination of rubber and metal creates multifunctional LEMFÖRDER automotive components that transmit forces, enable defined movements, isolate noise and dampen vibrations. Therefore, vibrations and noise caused by the transmission or the engine are hardly noticeable in modern vehicles - thanks to vibration-optimized concepts with innovative and safe powertrain mounts.

The intelligent connection between rubber and metal

Depending on the vehicle model, up to 15 rubber-to-metal components may be installed in a passenger car. The vulcanized connection between the metal and rubber transfers pressure and shear forces and simultaneously insulates oscillations, vibrations and structure-borne noise.

That is the reason why rubber-to-metal components have a decisive influence on driving characteristics and driving safety. The LEMFÖRDER composite parts are therefore designed in an innovative manner and are geared towards a particularly long service life.

Conventional, hydraulic or switchable engine mounts?

Conventional engine mounts are intelligently designed rubber-metal or rubber-plastic constructions that provide mechanical damping. Hydraulic engine mounts, also referred to as hydromounts, additionally work with an oil damping. Within the rubber element, the liquid ensures a flow resistance that softens jolts and vibrations. Hydraulic mounts are used wherever an elastic mounting with frequency-dependent damping is desired – on engine mounts, link mounts or axle housing mounting, for instance.

Switchable hydraulic mounts or active mounts can also adjust the damping characteristics of the unit to its respective operating condition via gear changes.

Task and function of rubber-to-metal mounts in the driveline

As a connection between the engine and the body, engine mounts absorb the static engine load. They limit the engine movement, thus ensuring a damping of the vibration and structure-borne noise transfer into the body.

Benefits of LEMFÖRDER engine mounts:

- Engine mount individually aligned to the engine perfomance

- Complex and harmonized internal structure

- With hydraulic engine mounts, the hydraulic function takes care of the damping

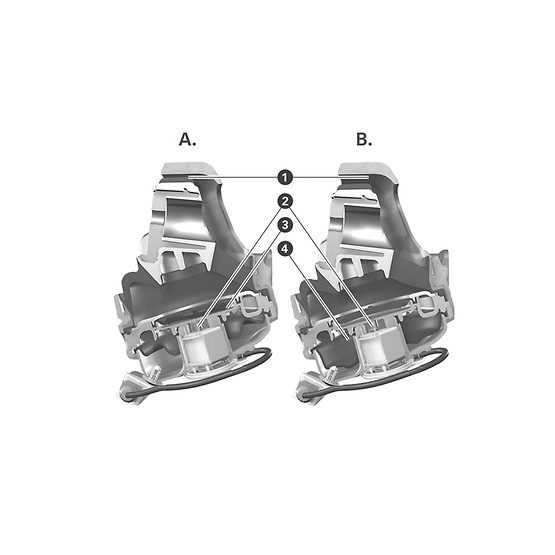

Functionality of the switchable engine mount

Re. A: In the comfort position, the valve (2) is open and, as a result, permits the motion of the air suspension (3). The result is a soft range of spring (1).

Re. B: In the driving dynamic position, the valve (2) is closed and, as a result, permits the motion of the hydraulic area (4). The result is a dynamically hard range of spring(1).

Advantages of intelligent damping:

The electronically switchable engine mount combines hard and soft suspension.

- It improves vibrational comfort.

- It improves the high frequency behavior.

- The set-up of the mounts in terms of rigidity, damping positions, and neutral position behavior is customizable.

Transmission mounts connect the transmission with the body. In doing so, they ensure a damping of the vibration and structure-borne noise transfer into the body.

![ZF Service [pro]Tech ZF Service [pro]Tech](/media/master/service-images/zf_workshop_protech_group-in-front-of-workshop_bs_32_xl_4.jpg?v=3456034853)

![[pro]Academy [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)