ZF Aftermarket product portfolio

ZF Aftermarket truck and bus steering and suspension parts and systems are safety-relevant components of outstanding quality which are subject to special diligence during design, production and assembly. After all, they have to provide optimum safety in any driving situation.

The LEMFÖRDER product portfolio

Steering parts

LEMFÖRDER steering parts for trucks and buses meet high demands: They pay off. This is because we offer complete solutions and ready-to-install manufacturer products that make repair and replacement easy. Downtime of commercial vehicles can thus be reduced to a minimum. LEMFÖRDER steering parts have prevailed on the truck and bus markets thanks to freedom of maintenance, low weight, an individual and space-saving design as well as long service life. The spare parts for the aftermarket also feature this original equipment quality.

The drag link transfers the steering movement introduced into the steering gear to the steerable wheels.

The tie rod transfers the steering movements of the wheel carrier steered by the drag link laterally through the vihicle to the steering knuckle/wheel carrier on the other side.

With the tie rod with fine-tuning system, it is possible to perform the tracking alignment on the curved tie rods and drag links while in a mounted condition.

The steering drag link serves to connect controlled axles.

The angle joint/ball joint on the drag links and tie rods transfers the force to the connecting components and compensate for movements.

Chassis components

LEMFÖRDER chassis components for commercial vehicles, trucks and buses are permanently reliable components, no matter how much they are stressed. Continuously improved product innovations also increase payloads, reduce fuel consumption and optimize the driving dynamics of trucks and coaches. Our focus is not only on new developments, but also specifically on the aftermarket.

Trucks and buses require torque rods for safe axle guidance - also known as axle guiding control arms, wishbones or axle struts. These parts connect the axle longitudinally, transversely or diagonally with the vehicle frame.

The precision products from LEMFÖRDER always guarantee accurate axle guidance due to their design. This contributes to the reduction of tire wear.

Due to design optimization, such as the use of casting technology, LEMFÖRDER has been able to successfully reduce the weight of torque rods for commercial vehicles thanks to continuous development work. Of course, without neglecting the most important factor that applies to all chassis components: safety.

LEMFÖRDER V-links for commercial vehicles, trucks and buses – also known as wishbones or v-rods – are maintenance-free and robust. The new developped weight-reduced versions allow higher payloads for commercial vehicles.

LEMFÖRDER wishbones for trucks and buses accomplish the absorption of longitudinal and lateral forces and, in conjunction with trailing arms and axle struts, take on all axis control tasks.

LEMFÖRDER stabilizer rods for trucks, commercial vehicles and buses play an important role in the design of vehicle suspension: they ensure safe road holding in bends.

As a result, roll and sway of the vehicle body are reduced, leading to improved vehicle stability and ride comfort, especially when it comes to fully loaded trucks or fully occupied buses.

Comfort, safety and service life are increasingly important aspects concerning the chassis. In terms of design, torque rods are developed with plain bearings or molecular bearings. For the event of damage – caused for example through wear – we offer complete repair kits that enable a repair at costs which reflect the current market value.

With the LEMFÖRDER repair kit, the workshop obtains all genuine parts in a single package with all required components. This enables a fast and inexpensive service.

An optimally adjusted wheel suspension or wheel guidance equals ride comfort for the driver and passengers. Furthermore, the independent suspension makes it possible to have the middle area of the bus, and consequently, the entry height much lower. The transverse control arm plays a huge role when it comes to this type of separate wheel suspension. It connects the vehicle body with the wheel via joints and therefore has a decisive influence on the drivability when cornering, accelerating, and braking. Alternative manufacturing methods and materials such as aluminum reduce its weight and aid in saving resources.

With the innovative LEMFÖRDER RL 75 E and RL 85 E front axle systems for coaches, two systems based on the double wishbone principle are available that cover the entire range of full-size buses.

As part of the wheel suspension or wheel guidance, this LEMFÖRDER suspension joint transfers the radial guiding forces to the wheel as well as the axial spring and damping forces. It ensures easy manoeuvrability and increased ride comfort.

Supporting joints are wearing parts and should therefore be regularly checked after a certain mileage. After all, they support the weight of the vehicle and ensure stable road holding, which is an important aspect with city buses and coaches.

The four-point link for trucks - a joint development of LEMFÖRDER and MAN - is taking over the roll stabilization of large commercial vehicles in addition to the axle guidance system.

Four points to go ahead

The LEMFÖRDER four-point link was developed in cooperation with MAN Nutzfahrzeuge AG. It leads and stabilizes the rear axle of commercial vehicles. The four-point link from LEMFÖRDER is being developed as a weight-reduced variant made of fiber composite materials to meet the modern demands of lightweight construction.

The result of permanent optimization

The weight-reduced 4-point link by LEMFÖRDER combines lightweight construction and functional optimization with an improvement of the dynamic driving properties.

- Less weight: The forged control arm has been further developed and replaced by a cast control arm. This results in a 20% (12 kg) weight reduction. ZF is already working on a further development of the 4-point link. A prototype manufactured from glass-fiber reinforced plastics (GRP) is currently being tested.

- More functions: As the only solution of this type currently on the market, the 4-point link unites three chassis tasks in a single component: The longitudinal and transverse guidance of the axle as well as an active roll stabilization.

- Fewer parts: V-links, stabilizers, and other chassis connection components can be omitted as a result of the functional expansion. This configuration leads to a significant weight saving on the overall axle.

- Less assembly work: The reduced number of components means that assembly work is also reduced.

The TRW Product Portfolio

Linkage and suspension parts

The TRW Aftermarket range of linkage and suspension systems enables you to supply customers with high quality control arms, ball joints, tie rods and much more for commercial vehicles. Using low alloy steel and alternative metals like aluminium, TRW promises to provide excellent, high strength performance as well as improved efficiency to all commercial vehicles.

Every TRW product is produced to match the stringent original equipment (OE) specifications. With our Independent Aftermarket range, you can fit a selection of truck and trailer suspension parts to produce industry-leading performances.

- Five environmental tests help to improve safety in all conditions

- High quality materials for longer lasting performance, saving businesses money in the long term

All of the TRW commercial vehicle linkage and suspension parts are tested and examine to the limit, so we have complete control over every product that we supply. This allows us to, giving you peace of mind that whenever you choose TRW parts you are getting the very best.

The range of linkage and suspension parts available from the TRW Commercial Vehicles department includes:

- Steering columns

- Steering pumps

- Steering gears

- Pitman arms

- Tie rods

- Tie rods ends

- V-Links

- Radius rods

As this exhaustive list proves, TRW has everything covered when it comes to truck and other commercial vehicle linkage and suspension.

Calling on more than 4,000 technicians, designers, scientists and industry experts from our worldwide workforce, we produce the very latest parts for commercial vehicles for all manufacturers. This allows us to deliver parts that not only improve safety but also efficiency, keeping both you and your customer ahead of the rest.

TRW takes huge pride in all of our products, which is why we test them to the extreme before they go to market.

Safety and reliability are two of our core values, and we will never compromise on quality. That’s why all of our parts are tested beyond their reasonable limits, giving drivers peace of mind that they can trust their vehicle all of the time.

Our tests cover the following:

- Axial and radial elasticity

- Rotational ability

- Articulation

- Breakaway torque

- Pull and push out forces

We’ll also perform wear, fatigue, functional and rubber tests along with our five environmental tests to ensure that TRW parts can withstand any conditions.

TRW is never happy to rest on past laurels, which is why we took our commercial vehicle steering and suspension products to be tested in Germany by the FRAUNHOFER-INSTITUT independent test centre. Among the TRW parts that stood out from the crowd were the radius rods, tie rods and V-Links. Competing against six other industry leaders, these TRW products excelled, receiving top marks for durability, strength and performance. These tough tests highlighted that TRW products have the ability to perform better for longer under extreme pressure. This industry recognition is evidence that the TRW products can deliver real safety without compromise.

The results were testimony to TRW’s own testing policies, which serve to place the parts in extreme conditions that many drivers will never encounter. This means commercial vehicle drivers can have peace of mind that wherever they travel, because they can trust the TRW parts.

With your customers’ margins increasingly being squeezed and time being money, the need for high quality parts that reduce the amount of time spent off the road is critical. By giving them TRW over cheaper, lesser quality options, you will improve the performance of your customers’ commercial vehicles and save businesses money.

The TRW tie rod end features an exceptionally innovative design that is smaller, stronger and longer-lasting than ever before.

To support the fantastic performance of the TRW parts, we guarantee a premium level of customer service. TRW will supply full marketing support, providing paper and online catalogues, meaning that it has never been easier to find the correct product to match your requirements. With expert technical support as well, TRW will also make sure that all enquiries on commercial vehicle parts are addressed quickly and efficiently. You can find out more by browsing the individual product pages on our website.

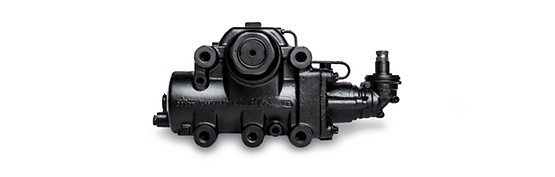

Steering Gears

TRW has been serving the commercial vehicle market since 1906. Today our steering gears are fitted in one-in-three European commercial vehicles, proving that we still meet the challenges faced by commercial vehicles.

- All parts meet the exacting standards of Original Equipment (OE) products

- We perform the most rigorous testing process available, ensuring that our steering gear parts are capable of performing safely and efficiently in all conditions

- TAS type steering gears produced with the fewest possible moving parts, so you can offer better torque output

- THP type steering gears, so you can offer drivers a faster steering ratio for improved turning and return-to centre response

- Industry-leading parts that last longer than competitors, saving money for your customer

Through TRW we can provide tailored solutions for drivers that cover a huge number of parts, and with independent experts placing us above other competitors, choosing TRW guarantees the very highest quality. Steering gears are employed to attach the steering wheel with the steering linkage of a vehicle. This is clearly a crucial part for the overall performance of a commercial vehicle, and steering gears that are faulty or worn out could be seriously dangerous for drivers. TRW parts will act to lengthen vehicle life, helping businesses to save time and therefore money in the long run with their trucks, buses or vans staying on the road for longer.

TRW was responsible for developing and producing the first boxed, OE-quality steering gears programme to the aftermarket. Our current catalogue of parts includes 33 TRW designed TAS and THP type gears:

- TRW TAS type steering gear – These are created with the fewest possible moving parts to ensure superior torque output and performance. They are ideal for vehicles on and off the highway that have medium and heavy front axle loads, helping to improve handling and steering control.

- TRW THP type steering gear – These gears are designed to provide a faster steering ratio that improves the lock-to-lock turns and return-to-centre response. With an optional, innovative Positive Centre Feel feature, drivers will also get an enhanced steering gear on-centre feel without having to increase the steering park effort.

All TRW parts are produced to the very highest standards that we set ourselves, and as a result they often exceed the industry-approved regulations. At our centre of excellence in Frydlant, Czech Republic, all parts are tested to the extreme using the following measures:

- Acoustic testing to ensure driver comfort

- Strength testing to help maximise durability

- Environmental resistance to ensure optimum ability for all weather conditions

- Drive tests for wear

- Safety features examined using assembly technique testing

- Leak-free performance dynamic testing

- On-road testing at TRW tracks

We also take our commercial vehicle steering and suspension parts to be tested independently, and in 2014 TRW parts went under the microscope at the renowned FRAUNHOFER-INSTITUT for Structural Durability and System Reliability. The outcome of these tests highlighted the exceptional performance of TRW parts, which outperformed six leading competitors, highlighting our ability to deliver real safety without compromise. With top marks for durability, strength and performance it is clear that choosing TRW ensures that you get the quality you need to help minimise vehicle downtime in the commercial industry.

Europe is a global leader in the commercial vehicle market and in May 2014, the number of van, bus and coach registrations grew, with the overall number of commercial vehicles increasing by a huge 10.8%. This highlights the unique opportunities that lie within this market, where choosing TRW means that you can deliver parts that will make a real difference on the road to businesses.

As operator costs increase year on year, it is becoming more and more important for business owners to keep their vehicles on the road for longer, as anytime off the road is time and money wasted. Opting for TRW steering gears will help you to provide your customers with a more viable economic option.

ACEA (the Association of European Automotive Manufacturers) has also noted that all commercial vehicles should be repaired with original spare parts or parts of matching quality, and TRW takes great pride in being able to offer this quality with all of our steering gear parts. We will remanufacture steering gears using TRW OE quality components that deliver exactly the same standards as new OE products.

XCap

TRW has been giving you solutions for the commercial vehicle aftermarket industry for many years now and our TRW department is constantly updating and improving our selection of parts. By fitting our XCAP ball joint, you can give your customers’ vehicles a stronger, more robust performance across all types of conditions and driving scenarios.

The XCAP has been designed for the future of steering and suspension technology, making it a must-have part for commercial vehicle drivers.

- The very latest steering technology

- The smallest and lightest component of its kind on the market delivering a more efficient performance

- Ball joints that last up to four times longer than competitors

- Enhanced dust cover design for better part protection

- Reduced torque to provide enhanced steering comfort

- More than 180 references to meet a variety of customer demands

As the heavyweight in safety, TRW can provide a huge choice of parts covering steering, suspension, brake pads, shock absorbers and more. Our new XCAP tie rod end is one of the most advanced vehicle parts ever produced.

Carefully designed, the XCAP has been tested to the extreme, providing you with peace of mind that it is a part that will not let drivers down. As a smaller, stronger and more durable product than previous ball joints, it will have a longer life and more efficient all round performance.

An enhanced cover also gives the XCAP ball joint excellent protection from wear and tear, while the reduced torque means improved steering comfort and smoother journeys for all. The overall result is that steering and suspension in commercial vehicles is boosted, making the XCAP a valuable addition to the steering and suspension range for you and your customers.

The parts on commercial vehicles experience extreme pressure owing to the huge amount of weight that they have to carry. Most commercial vehicles already have a heavy chassis and when you add on the weight of the load it is important that the component weight is as low as possible, otherwise the kinetic energy of the vehicle could be affected.

If this does happen then driver and load safety could be compromised. Unseen forces are placed on the parts every time the brakes and steering systems are used, which makes it critical that they stand up to the rigours of daily life. TRW tests all parts thoroughly to ensure they have the ability to perform at their best for longer.

When tested against leading competitors, the XCAP performed much better across a range of durability, performance and strength tests that were carried out by the FRAUNHOFER-INSTITUT in Germany for Structural Durability and System Reliability. Compared against six other market leaders, the TRW XCAP Ball Joints lasted up to four times longer than any others. While competitors showed signs of damage such as worn bearings, cone issues, dust cover faults and nut errors, the tests had no effect on the XCAP.

To achieve such impressive results from independent testing, we have to perform extreme examinations ourselves before we send any parts to market. With the XCAP tie rod ends this is especially important because we are the only manufacturer producing such a part. Our tests include:

- Assembly technique testing of all critical safety features

- Environmental resistance for all weather conditions

- Wear and drive tests

- Extensive road testing on TRW tracks across the world

- Acoustic measuring to help enhance driver experience

All of these tests fall in line with OE checks, which give you peace of mind that all TRW products will be as good as, and often better, than everything else available on the market.

You only need to look at our list of partners to see how we’re trusted in the industry. We’ve signed contracts with Daimler Trucks, Scania and Volvo Trucks that allows us to cover a wide part of Europe and South America.

With a large Original Equipment market share on tie rod ends as well as drag links and other important steering and suspension parts for commercial vehicles, it’s TRW that you can trust when it comes to robust, high-quality CV parts. Find out more about the full range of commercial vehicle parts and the XCAP by browsing our online catalogue today.

The Wabco Product Portfolio

Hydraulic steering gears

Features and innovation

- Transmitting force from the steering wheel to the steering gear

- Converting a rotational movement of the steering wheel into a pivoting movement of the pitman arm

Customer value

- Automatic bleeding system to improve steering performance and increase steering life within some variants or available as an option

- Optionally, improving feel of center steering and precision of straight-ahead driving to reduce driver fatigue and increase long-haul use

Difference

- Offering of two re-circulated ball type gears for HCV power steering systems

- Wide range of applications

![[pro]Academy [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)